A heat exchanger is a device used to transfer heat between two or more fluids. The fluids can be single or two phase and, depending on the exchanger type, may be separated or in direct contact.

In order to discuss heat exchangers it is necessary to provide some form of categorisation. There are two approaches that are normally taken. The first considers the flow configuration within the heat exchanger, while the second is based on the classification of equipment type primarily by construction. Both are considered here.

“Basically, arteries carrying warm blood to the skin get crossed and exchange heat with veins carrying cold blood away. The result is basically a “countercurrent” heat exchanger that reduces overall heat loss in cold waters — for baleen whales when the swallow enormous amounts of water to catch their evening krill, for storks, flamingos, and other wading birds when they stand in cool water, and for fish while breathing underwater.

No word yet if anybody has modeled an industrial machine after a blue whale.”

Classification of Heat Exchangers by Flow Configuration

There are four basic flow configurations:

- Counter Flow

- Cocurrent Flow

- Crossflow

- Hybrids such as Cross Counterflow and Multi Pass Flow

Countercurrent flow

|

Fig 1- Countercurrent flow |

Cocurrent flow

|

| Fig 2 - Cocurrent flow |

In cocurrent flow heat exchangers, the streams flow parallel to each other and in the same direction as shown in Cocurrent Flow, This is less efficient than countercurrent flow but does provide more uniform wall temperatures.

Crossflow

|

| Fig 3 -Cross Flow |

Crossflow heat exchangers are intermediate in efficiency between countercurrent flow and parallel flow exchangers. In these units, the streams flow at right angles to each other as shown in Figure 3.

Cross/counter flow

|

| Fig 4 - crossflow/counterflow |

In industrial heat exchangers, hybrids of the above flow types are often found. Examples of these are combined crossflow/counterflow heat exchangers and multi pass flow heat exchangers. (See for example Figure 4.)

Classification of Heat Exchangers by Construction

|

| Fig 5 - Classification of Heat Exchangers |

Regenerative Heat Exchangers

Regenerators are mainly used in gas/gas heat recovery applications in power stations and other energy intensive industries. The two main types of regenerator are Static and Dynamic. Both types of regenerator are transient in operation and unless great care is taken in their design there is normally cross contamination of the hot and cold streams. However, the use of regenerators is likely to increase in the future as attempts are made to improve energy efficiency and recover more low grade heat.

In a regenerative heat exchanger, the flow path normally consists of a matrix, which is heated when the hot fluid passes through it.

Recuperative Heat Exchangers

There are many types of recuperative exchangers, which can broadly be grouped into indirect contact, direct contact and specials. Indirect contact heat exchangers keep the fluids exchanging heat separate by the use of tubes or plates etc.. Direct contact exchangers do not separate the fluids exchanging heat and in fact rely on the fluids being in close contact.

Indirect heat exchangers

In this type, the steams are separated by a wall, usually metal.

Tubular heat exchangers are very popular due to the flexibility the designer has to allow for a wide range of pressures and temperatures. Tubular heat exchangers can be subdivided into a number of categories, of which the shell and tube exchanger is the most common.

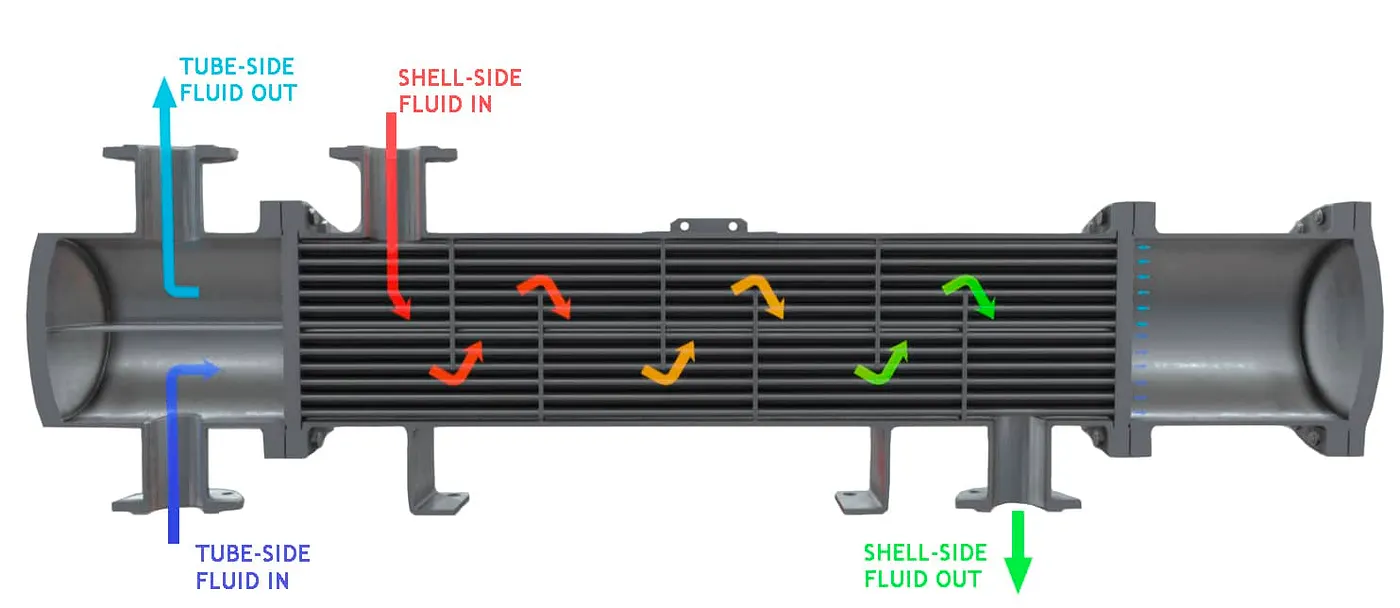

Shell and tube heat exchanger

Shell and tube heat exchangers have a simple design, robust characteristics and relatively low purchase and maintenance costs. They also have a very high heat transfer rate.

|

| Fig 6 - Shell and tube heat exchanger |

Two fluids can exchange heat, one fluid flows over the outside of the tubes while the second fluid flows through the tubes. The fluids can be single or two phase and can flow in a parallel or a cross/counter flow arrangement. The shell and tube exchanger consists of four major parts:

- Front end–this is where the fluid enters the tubeside of the exchanger.

- Rear end–this is where the tubeside fluid leaves the exchanger or where it is returned to the front header in exchangers with multiple tubeside passes.

- Tube bundle–this comprises of the tubes, tube sheets, baffles and tie rods etc. to hold the bundle together.

- Shell — this contains the tube bundle.

Plate and Frame Heat Exchangers

Plate and Frame Heat Exchangers consist of two rectangular end members which hold together a number of embossed rectangular plates with holes on the corner for the fluids to pass through. Each of the plates is separated by a gasket which seals the plates and arranges the flow of fluids between the plates.

This type of exchanger is widely used in the food industry because it can easily be taken apart to clean.

Plate Fin Exchangers consist of fins or spacers sandwiched between parallel plates. The fins can be arranged so as to allow any combination of crossflow or parallel flow between adjacent plates. It is also possible to pass up to 12 fluid streams through a single exchanger by careful arrangement of headers.

Spiral plate exchangers are formed by winding two flat parallel plates together to form a coil. The ends are then sealed with gaskets or are welded. They are mainly used with viscous, heavily fouling fluids or fluids containing particles or fibres.

Direct contact

This category of heat exchanger does not use a heat transfer surface, because of this, it is often cheaper than indirect heat exchangers. However, to use a direct contact heat exchanger with two fluids they must be immiscible or if a single fluid is to be used it must undergo a phase change.

Specials

The wet surface air cooler is similar in some respects to an air cooled heat exchanger. However, in this type of unit water is sprayed over the tubes and a fan sucks air and the water down over the tube bundle. The whole system is enclosed and the warm damp air is normally vented to atmosphere.

Static Regenerators

Static regenerators or fixed bed regenerators have no moving parts except for valves. In this case the hot gas passes through the matrix for a fixed time period at the end of which a reversal occurs, the hot gas is shut off and the cold gas passes through the matrix.

Rotary regenerator

In a rotary regenerator cylindrical shaped packing rotates about the axis of a cylinder between a pair of gas seals. Hot and cold gas flows simultaneously through ducting on either side of the gas seals and through the rotating packing.

Applications

- Crude oil cooling:

Heat exchanger between crude oil that goes into the furnace with a residue that goes into the cooler so that the heat contained in the residue can be utilised to raise the temperature of the crude oil and the load of the furnace becomes lighter. The type of Heat exchanger used is Shell and Tube Heat Exchanger, which consist of 3 pieces arranged in series.

2. Condensor:

Equipment used to reduce the temperature of the vapour to the liquid temperature by leaving the heat to another fluid. One of the streams is a fluid (vapour) to be condensed, usually, steam from the top of the distillation column or fractionation.

3. Evaporator:

An evaporator is a device used to evaporate a solution. Evaporation itself means removing water from the solution by boiling the solution in the evaporator tube.

Subscribe Our Newsletter

0

Post a Comment